Handling Major Spills: Best Practices for Safety and Compliance

In industrial and commercial environments, major spills pose a significant risk to both personnel and the surrounding environment. From chemical leaks to hazardous material releases, the consequences of mishandled spills can range from serious injuries and environmental contamination to regulatory penalties, financial losses, and reputational damage. Businesses that manage or store hazardous substances must prioritize spill preparedness, ensuring that employees are properly trained, protocols are rigorously enforced, and response measures fully align with industry safety standards. A proactive approach not only reduces the immediate dangers of spills but also strengthens overall workplace safety culture, operational efficiency, and long-term regulatory compliance.

Understanding the complexities of major spill management requires a clear grasp of regulatory requirements, appropriate equipment usage, and systematic response strategies that cover all potential scenarios. Effective spill handling goes beyond simply cleaning up the substance; it involves containment, hazard assessment, proper disposal, ongoing monitoring, and meticulous documentation to ensure compliance with local, state, and federal regulations. By following established best practices, organizations can minimize risks, protect their workforce, prevent environmental harm, and demonstrate strong environmental responsibility. In this guide, we explore essential strategies for handling major spills safely and effectively, including preparation, response, cleanup, and compliance measures. These actionable insights provide a roadmap for businesses committed to mitigating risks while maintaining operational continuity and safeguarding their reputation.

1. Preparing for Major Spills

Risk Assessment and Hazard Identification

Preparation begins with understanding what types of spills are most likely to occur in your facility. Conducting a thorough risk assessment helps identify hazardous materials, their storage locations, and potential spill scenarios. This includes evaluating the chemical properties of substances, such as flammability, reactivity, and toxicity, which influence the appropriate response method.

For instance, an industrial site handling corrosive acids requires specialized containment strategies distinct from those used for oil or non-toxic liquids. Creating a detailed inventory of chemicals, coupled with Material Safety Data Sheets (MSDS), ensures responders can quickly access critical information during an emergency.

Spill Prevention Measures

Preventive measures are the first line of defense against major spills. Implementing secondary containment solutions, such as spill pallets or berms, reduces the likelihood of hazardous materials escaping primary storage containers. Regular maintenance of equipment, proper labeling, and staff training on safe handling procedures further minimize risks.

A real-world example is the manufacturing sector, where companies often install drip trays under tanks and use automated sensors to detect leaks early. This proactive approach significantly lowers the chance of a full-scale spill, saving both costs and potential regulatory headaches.

2. Immediate Response to Spills

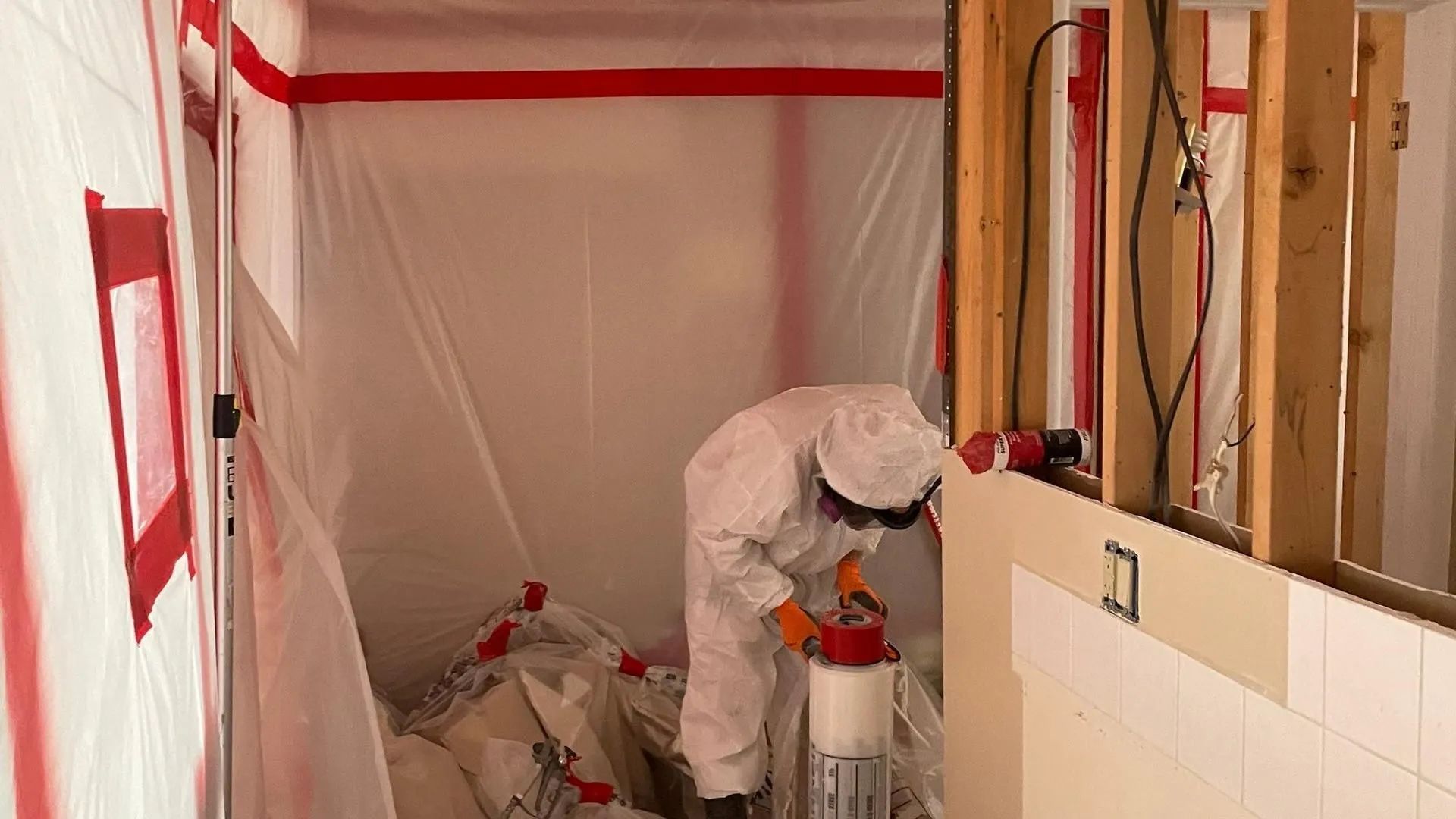

Safety First: Protecting Personnel

When a spill occurs, the priority is always human safety. Employees must follow established protocols, don appropriate personal protective equipment (PPE), and evacuate non-essential personnel from the affected area. Depending on the material, PPE may include gloves, goggles, chemical-resistant suits, or respiratory protection.

For example, a chlorine gas leak requires rapid evacuation and specialized respirators, while a spill of non-toxic water-based chemicals may require only gloves and protective footwear. Providing clear instructions and training ensures staff can respond swiftly and safely, reducing the risk of injury.

Containment Techniques

Containment is critical to preventing a spill from spreading and causing further damage. Using absorbent materials, barriers, or spill kits can isolate the substance. In liquid chemical spills, containment booms or dikes are often deployed to stop the material from reaching drains or open areas.

A practical scenario is in warehousing facilities, where oil or fuel leaks can quickly infiltrate stormwater systems. Prompt deployment of containment measures prevents environmental contamination and limits cleanup complexity.

3. Cleanup and Decontamination

Choosing the Right Cleanup Methods

Proper Disposal Practices

Decontamination of Equipment and Surfaces

4. Regulatory Compliance and Documentation

Understanding Legal Requirements

Compliance with environmental and occupational safety regulations is a critical aspect of major spill management. Regulatory bodies, such as the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA), provide guidelines on handling, reporting, and disposing of hazardous substances.

Businesses must ensure that response plans adhere to these regulations to avoid legal penalties. For example, large-scale chemical spills often trigger mandatory reporting, and failure to notify authorities can lead to significant fines. Awareness of local regulations, in addition to federal requirements, ensures comprehensive compliance.

Maintaining Accurate Records

Detailed documentation of spill incidents is essential for regulatory compliance and future prevention efforts. Records should include the type and quantity of material spilled, containment and cleanup methods, personnel involved, and any injuries or environmental impacts.

Real-world benefits of thorough documentation are evident in industries such as chemical manufacturing, where historical spill data informs safety audits and risk assessments. Maintaining accurate records demonstrates due diligence, supports continuous improvement, and can be crucial in legal proceedings or insurance claims.

5. Training and Preparedness Programs

Employee Training

Effective spill management relies on well-trained staff. Regular training programs should cover hazard recognition, PPE usage, spill response procedures, and emergency communication protocols. Scenario-based drills enhance readiness and ensure employees can respond under pressure.

A practical example is in the pharmaceutical industry, where regular mock spills of non-hazardous materials help staff practice containment, cleanup, and reporting procedures without exposure to real hazards. Such training builds confidence and reduces the risk of errors during actual emergencies.

Emergency Response Planning

Comprehensive spill response plans outline responsibilities, communication channels, and step-by-step actions during an incident. These plans should be accessible, reviewed regularly, and updated based on lessons learned from past incidents.

Facilities often include a dedicated spill response team trained to handle specific types of hazardous materials. Regular reviews and tabletop exercises help refine response plans, identify gaps, and enhance overall preparedness.

6. Challenges and Best Practices

Common Challenges

Managing major spills presents several challenges. These include unpredictable spill behavior, limited access to hazardous areas, resource constraints, and the potential for human error. Environmental factors such as weather conditions or nearby water sources can further complicate containment and cleanup efforts.

For example, outdoor chemical spills during heavy rain may spread rapidly into storm drains, necessitating immediate deployment of portable containment systems. Anticipating and planning for these variables is critical for successful spill management.

Industry Best Practices

Implementing industry best practices improves both safety and efficiency in spill response. Key strategies include:

- Conducting regular risk assessments and safety audits.

- Stocking accessible and well-maintained spill kits.

- Providing comprehensive employee training and refresher courses.

- Developing clear communication protocols for emergencies.

- Reviewing and updating spill response plans regularly.

- Engaging professional hazardous material contractors for high-risk scenarios.

Following these practices not only mitigates risk but also reinforces regulatory compliance and demonstrates organizational commitment to environmental stewardship. Businesses that invest in preventive measures and staff preparedness are better positioned to respond effectively, minimizing potential harm to people, property, and the environment.

Actionable Steps for Protecting People and Environment

Handling major spills is a critical responsibility for organizations that deal with hazardous materials. By prioritizing preparation, immediate response, proper cleanup, and regulatory compliance, businesses can minimize risks and protect both personnel and the environment. Effective spill management requires a combination of training, practical equipment, clear protocols, and thorough documentation. Organizations that implement these best practices reduce operational disruptions, maintain regulatory compliance, and enhance workplace safety culture.

At

The Asbestos Company, we understand the complexities and risks associated with hazardous material spills. Based in Northglenn, Colorado, with 25

years of experience, we have developed comprehensive strategies for safe handling, containment, and disposal of hazardous substances. Our team combines expert knowledge with hands-on experience, ensuring that every spill is managed with precision and compliance. Whether advising on preventive measures, training staff, or executing emergency responses, we provide reliable solutions tailored to each client’s needs. Partnering with The Asbestos Company

ensures safety, regulatory adherence, and peace of mind for any facility handling hazardous materials.